Cooling towers are indispensable components of industrial and commercial cooling systems, ensuring proper temperature control and system efficiency. However, one persistent challenge that cooling towers face is scaling, which can drastically reduce performance and increase operational costs over time. A promising, sustainable solution lies in the use of Electromagnetic Field (EMF) technology. This blog explores how EMF can transform cooling tower maintenance, reduce scaling, and improve overall system efficiency.

Understanding Scaling in Cooling Towers

Scaling is the accumulation of mineral deposits, primarily calcium carbonate and magnesium salts, on cooling tower surfaces such as heat exchangers, pipes, and fill media. These minerals are naturally present in the water used in cooling towers and become concentrated as water evaporates, leaving behind hard deposits. Over time, these deposits act as an insulating layer, obstructing heat transfer and reducing system efficiency.

The Impact of Scaling

Scaling can have severe consequences on cooling tower operations, including:

- Reduced Heat Transfer Efficiency: Scale buildup creates an insulating barrier that impedes effective heat transfer.

- Increased Energy Consumption: Systems must work harder to maintain cooling performance, driving up energy costs.

- Frequent Maintenance and Repairs: Scaling necessitates labour-intensive cleaning, frequent component replacement, and system downtime.

- Shortened Equipment Lifespan: Continuous exposure to scaling can corrode and damage system components, leading to premature failure.

How EMF Technology Works

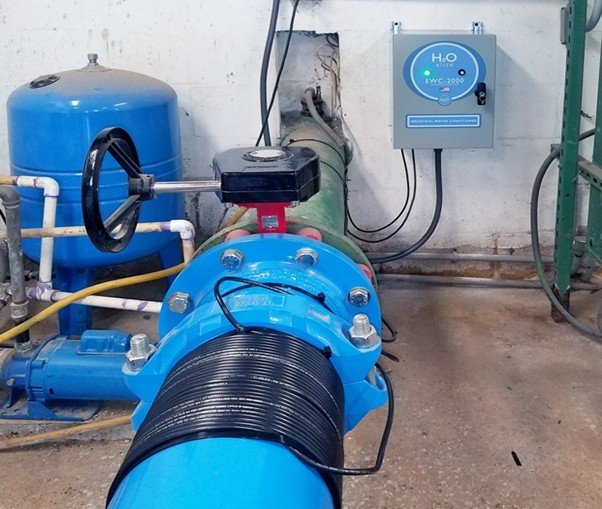

Electromagnetic Field (EMF) technology uses controlled electromagnetic waves to alter the behaviour of mineral ions in water. When water passes through an EMF system, the electromagnetic field disrupts the crystallization process of minerals, preventing them from adhering to surfaces and forming scale. Instead, the minerals remain suspended in the water and are carried away during regular blowdown cycles.

Key Benefits of Using EMF for Cooling Towers

- Prevention of Scaling and Corrosion

Unlike chemical treatments that address existing scale, EMF actively prevents scaling from occurring. By keeping minerals suspended, it also minimizes corrosion caused by localized deposits, thereby protecting cooling tower components. - Improved Energy Efficiency

With minimal scaling, cooling systems operate at optimal efficiency. Heat transfer surfaces remain clean, reducing energy consumption and lowering operational costs. - Reduced Maintenance Requirements

EMF technology significantly reduces the need for manual cleaning, chemical dosing, and frequent repairs. This leads to decreased labour costs, minimized system downtime, and fewer disruptions to operations. - Elimination of Chemical Dependency

Traditional chemical treatments rely on biocides, anti-sealants, and corrosion inhibitors, which can be expensive and environmentally hazardous. EMF technology eliminates or drastically reduces the need for these chemicals, promoting sustainability. - Extended Equipment Lifespan

By preventing scale and corrosion, EMF technology prolongs the life of critical components like heat exchangers, pumps, and pipes, delaying the need for costly replacements.

Why EMF is a Better Option than Chemical Treatments

While chemical treatments have been the go-to solution for managing scaling, they come with significant drawbacks:

- Environmental Concerns: Chemical treatments introduce harmful substances into water systems, posing risks to ecosystems and complicating regulatory compliance. In contrast, EMF technology is chemical-free, offering an eco-friendly alternative.

- Cost of Continuous Chemical Usage: Chemical programs require ongoing purchases of inhibitors, biocides, and other agents. These costs add up over time, whereas EMF systems have minimal ongoing expenses.

- Maintenance and Monitoring Challenges: Chemical treatments require constant monitoring and adjustments to maintain effectiveness. EMF systems, on the other hand, operate automatically and require little intervention, reducing operational complexity.

- Limited Effectiveness: Chemical treatments are often less effective against all types of scaling and can leave some deposits untreated. EMF technology ensures comprehensive prevention by addressing scaling at its root.

Conclusion

EMF technology represents a transformative solution for cooling tower treatment, addressing the limitations of traditional chemical approaches. By preventing scaling, reducing energy consumption, and minimizing environmental impact, EMF provides a sustainable and cost-effective alternative. For industries seeking to enhance operational efficiency and meet sustainability goals, adopting EMF technology is a forward-thinking investment.

References & Further Reading

- Cooling Technology Institute (CTI): “Best Practices for Cooling Tower Treatment.” www.cti.org

- ASHRAE Guidelines: “Guidelines for the Maintenance and Operation of Cooling Towers.” American Society of Heating, Refrigerating, and Air-Conditioning Engineers.

- “The Economics of Scaling Prevention in Industrial Cooling Systems” – Energy Efficiency Journal.

- “Advancements in Electromagnetic Water Treatment” – Greentech Innovations Blog.

- “Sustainable Water Management in Industrial Cooling Systems” – Environmental Impact Journal.